Production of vaccines

The revolution of Bio-tech began in 1970s with genetic engineering, fermentation and vaccines etc; Which has major impact on research and production of vaccine. The vaccines were easy with the effect of re-combinant DNA technique, where the production and isolation of key antigens was either not possible or difficult and too expensive in previous days. On addition of advance in production methodology for more traditional vaccines, have resulted in improvement of yields, in case of manufacturing and better adherece practices.

Vaccine work by preparing the immune system to battle combat infection and disease. They are biological products which are the results of series of sophisticated and careful processes that ensure the quality of each dose.

Here is the method of how vaccines are made;

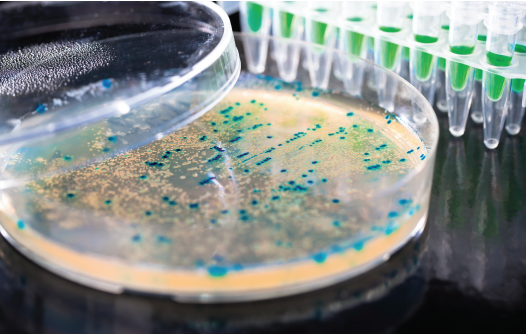

· Preparation: Production starts with culturing (growing) viruses or bacteria in microbiology lab with wide range of parameters which are managed,and they are like temperature , pH , oxygen rate,sterility and homogeneity. The slightest variation in culture media effect the production of vaccine.

· Purification : The microorganisms are extracted from their environment through a process called purification, which eliminates any trace of Culture Media.

·

INACTIVATION

: Then to inactivate the viruses or bacteria,that is, to eliminate its ability to

cause disease, we disarm it,but we retain its ability to elicit the precautionary

immune response from the body that is inactivated in viruses or bacteria is called as valence.

· Combination mixing : A vaccine can include one or several valences to protect against one or multiple diseases in the same shot. Each valence must remain fully effective and it must not interfere with other valence, as this careful precise combination takes years for scientific research and development to have perfection. Then, stabilizer or a preservative is added in extremely small quantities to help guarantee that the vaccine will remain stable, potent and effective. Sometimes an adjuvant is also added to enhance the body's immune response to the vaccine.

· Storage and transportation : Certain vaccines are also freeze-dried into a powder to help further preservation of the vaccines efficacy, which is particularly important for vaccines that are intended to prevent outbreak prone diseases like yellow fever. Having available stocks on hand over time is an important element for combating and containing disease. When it's time for the vaccine to be administered, it will be reconstituted by combining this powder with a diluent. The vaccine in liquid or freeze-dried form and diluent is needed, and are then filled into vials or syringes when the filling phase is complete. Each vial or syringe undergoes visual inspection. The quality of the contents and the containers are scrutinized by both the human eye and state-of-the-art digital surveillance technology. All along, the production of each and every batch of vaccine to confirm quality, in addition, samples are taken from each batch and sent to public health authorities for testing. Only after the vaccines have successfully passed both the sets of tests and distribution, the next step is taken. There are no exceptions of vaccine, if a batch does not meet the quality criteria, and it will be destroyed later on.

throughout the process of packaging and shipping, vaccines must be stored between 2 and 8 degrees Celsius cold rooms and temperature controlled shipping solutions such as refrigerated containers and isothermal packaging. This protects the vaccines during each phase of transportation and a temperature tracking device is included in each shipment.

Sterile conditions are implemented, where the atmosphere is also purified continuously to control the production chain and to ensure the raw materials and equipments are made sterile throughout the manufacturing process, so that the finished products are of the highest quality. In total, more than 70% of the time required to produce a vaccine is spent on these quality controls. Depending on the vaccine, we conduct up to 1200 different tests throughout the whole process. For these reasons the total time required to produce a vaccine ranges high, and the vaccine for flu requires 6 months all together.

-Ramnath P

Good information on production of vaccines

ReplyDelete